Mark’s Trains specialise in the conversion of analogue models to digital control. Restoring and servicing old model trains is part of the service that we provide to our customers. Giving customers the opportunity to have these old collectables converted to digital control brings them into the modern world and extends their useful life. And why not? If they are still going strong and work perfectly well, why should age consign them to the scrap heap?

Restoring models manufactured from as far back as the 1950s by the likes of Hornby Dublo, superseded by Tri-ang Hornby from the mid-60s to early 70s before transitioning over to Wrenn in the early 70s (who had bought the tooling from Tri-ang Hornby), can be quite satisfying. For example, we can have a two-rail electric locomotive with a die cast heavy metal body, built to last the test of time, still working as if it had just left the factory.

However, this isn’t always the case. Over the years the grease on the bearings and gears can harden. This puts a heavy strain on the motor and drive gears. Grease and oil contaminate brushes, and motor magnets lose their strength owing to age or heat from transmission resistance. Motor armature coils become brittle over time too, and eventually break down and stop the motor from working. Or it burns out altogether. All is not lost, though.

Restoration

With a little bit of TLC, we can clean the drive gears and bearings, strip and clean the motor, rewind the armature coils and re-magnetised the magnet. Finally, with new brushes and a light lubrication of the bearings and gears, the model is ready to test. We give it a good run in both directions. This helps spread the oil and loosen any tight bearings and beds in the new brushes.

Conversion to digital control

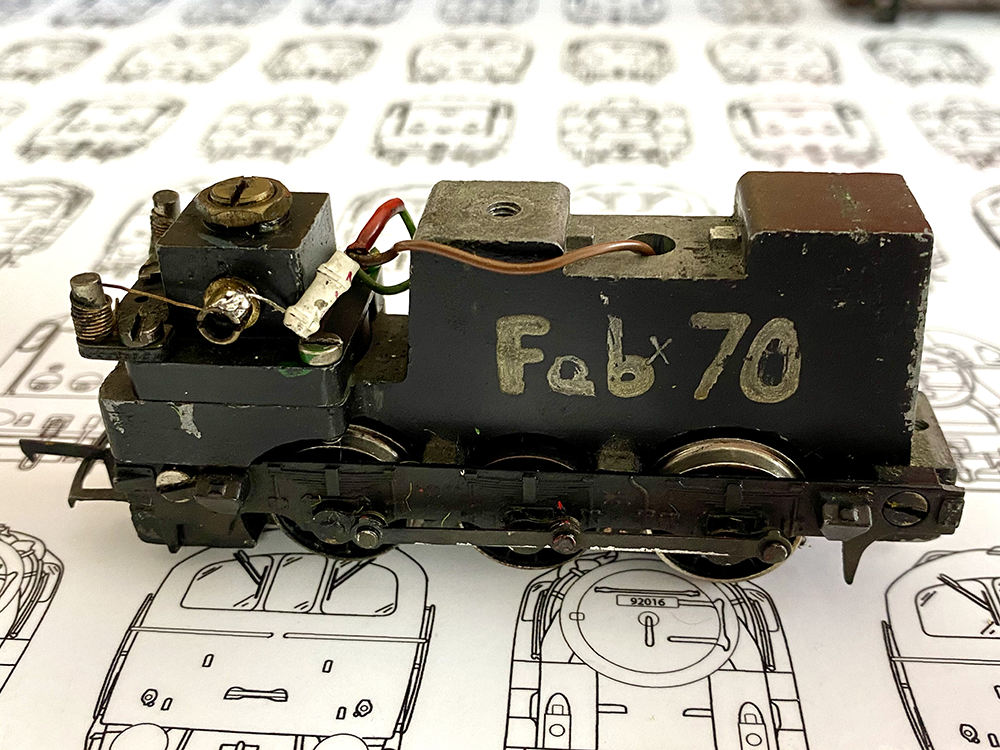

The locomotive is now running just like it did when it left the factory. So next comes the conversion to digital control. This will bring this locomotive a new lease of life in the modern world of railway control. Firstly, we need to insulate one of the motor brush sleeves so that it doesn’t cause a short circuit. On analogue control, power from one of the rails goes through the body to the brush sleeve then to the brush itself.

Did you know…?

Analogue control consists of a mains-powered 12-volt power supply with a rotary dial. Rotating from zero through to maximum changes the voltage to the tracks from 0 to 12 (or 15) volts DC (direct current). Locomotives can be quickly tested using a 9v smoke alarm battery placed between the wheels or a piece of clean track.

Digital control known as ‘Digital Command and Control’ or DCC for short, is a modern version of train control. A constant fixed voltage is applied to the rails (approximately 14 volts), which carries a digital signal. This directs specific addressed locomotives to move or stop, along with many other advanced features. The digital signal consists of pulses carried along the power supply. This is analogous to a phone line with internet data flowing along it. The two can be separated, so that power is available constantly at the rails for things like streetlights, etc. In addition, the signal or control aspect is carried along inside very small, rapid pulses to the chip inside the locomotive. The chip on board the addressed locomotive picks up this signal and acts accordingly.

Why digital is better

The advantage of digital control is that many trains can be separately controlled on a single track connected to just two wires. In contrast, two wires from an analogue controller to a section of track with the same trains will see all of them operate in the same manner.

Digital control therefore simplifies the wiring of model railway layouts, as only two wires are needed for the whole layout. Controlling analogue trains individually requires a bank of switches and many sections of isolated track along with a bird’s nest of wiring. Digital control is much simpler to use. Select the programmed locomotive chip number you want to control, and only that train will move.

Digital control requires that both motor brushes are isolated from the track power, as the controller chip sits between the two to control the motor speed and direction. We need to carry out some modification on the motor housing to remove the original metal brush sleeve and replace it with an insulated version.

Once we have completed this, we connect the brushes and track power feeds to the controller chip. At this stage, the locomotive is ready to program and test under digital control, with a new address assigned to the locomotive during programming. The locomotive is now in the digital age, and despite its age runs just as good as a recently manufactured model. This will give the locomotive many extra years of life.

To find out more about the services Mark’s Trains provides, or to book a conversion, visit www.marks-trains.co.uk.